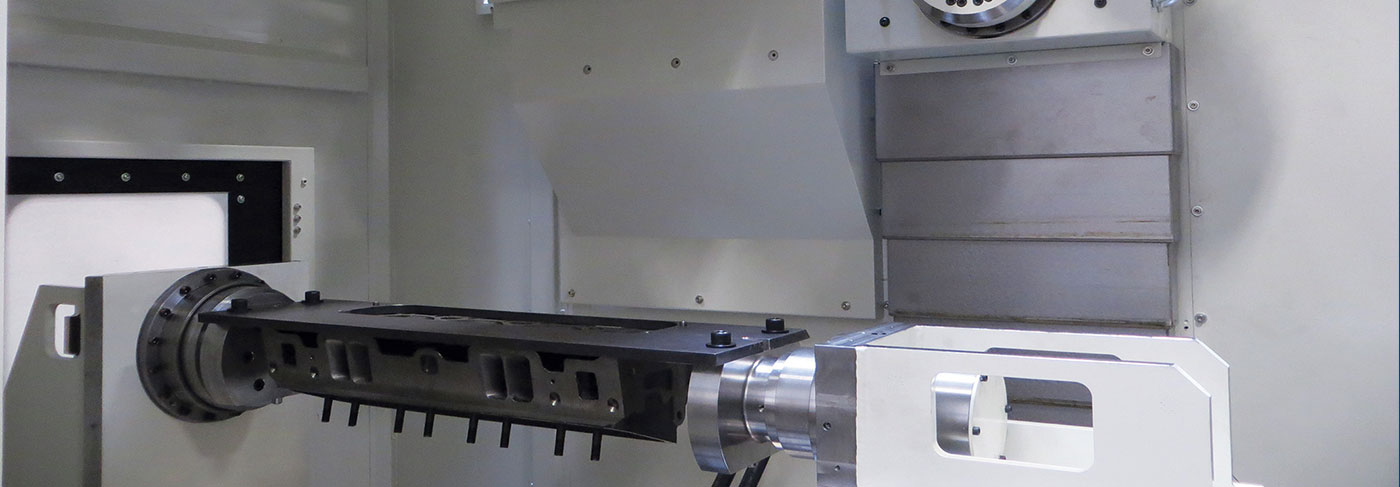

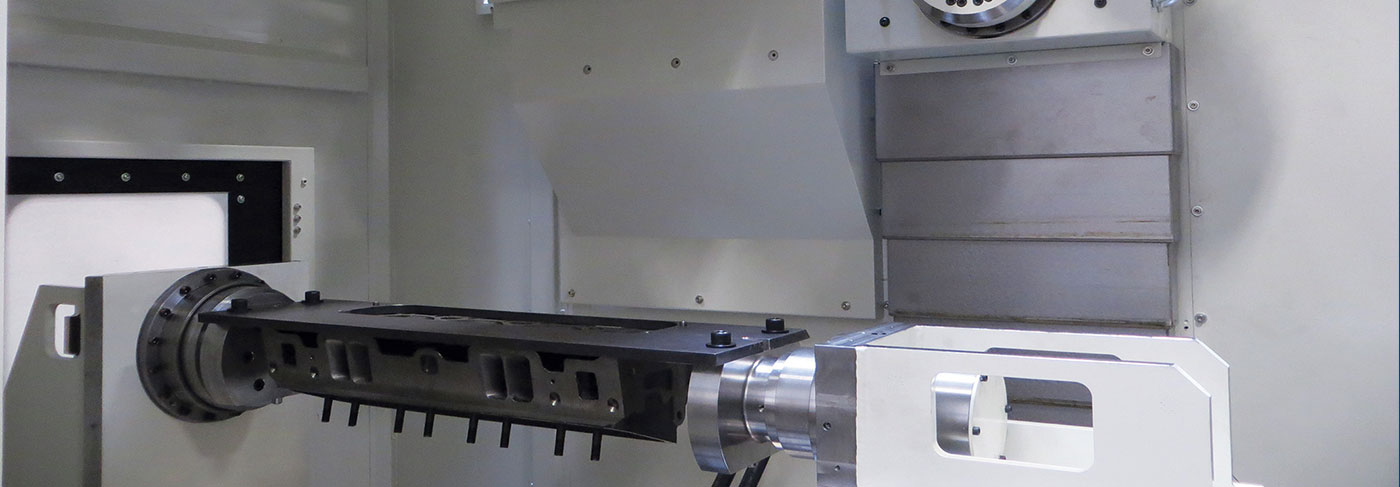

5 Axis CNC Machining

5-Axis CNC machining breaks the barriers of conventional machining and can produce high-precision, mission-critical parts. Our five-axis CNC machining services allow custom parts with extreme multi-axis complexity to be machined on time and on budget.

With a variety of metals and plastics, including aluminum, titanium, steel, ABS, PP, etc., HongZhongxin has the ability to provide you with customized 5-axis CNC machined parts.

Our factories and partners have world-class equipment, knowledge and expertise. Whether you need individual parts or mass production, our 5-axis CNC lathes and experienced team can manage the entire process for you.

Which parts are suitable for processing?

1. Parts with complex shape and poor opening of processing channels

Widely used in the automotive industry for component prototyping and production, it can perfectly handle the complexity of parts, such as: engine housing, engine cover, valves, inspection fixtures, light guides, etc.

2. Parts with complex surfaces and large surface areas require higher cutting efficiency

Widely used in the military and aerospace fields, it can perfectly handle the geometric aspects of parts and maintain integral processing, such as: turbine blades, submarine parts, engine parts, sensors, weapons, bulkheads, fuselage parts, landing gear parts, etc.

3. High precision and large volume parts

Medical devices often need to process fine surfaces and small parts, and five-axis machining centers can meet their high-precision and high-efficiency processing needs. For example: scalpel, surgical scissors, tweezers, clips, cutters, gaskets, etc.

Three-axis machining parts can be used, but considering certain factors, five-axis machining is sometimes proposed.

5 axis machining material

We have cited some commonly used processing materials, but it does not mean that we can only do these materials, as long as there are on the market, and you have the demand, we have the ability to process.

| Aluminum Machining | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

| Stainless Steel Machining | 55201, 55301, 55303, SS304, 55316, 55416, etc. |

| Steel Machining | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc. |

| Brass Machining | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper Machining | C11000, C12000, C12200, C10100, etc. |

| Iron Machining | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic Machining | POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc. |

5 axis machining tolerances

| Standards | Metric Units | Imperial Units |

| Maximum Part Size | 300×200×100 mm | 11.8×7.7×3.9 in. |

| Minimum Part Size | 4×4×4 mm | 0.1×0.1×0.1 in. |

| Minimum Feature Size | Φ 0.50 mm | Φ 0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-f |

| Plastics: ISO 2768-m |

| Linear dimension | +/- 0.025 mm | +/- 0.001 in. |

| Hole diameters (not reamed) | +/- 0.025 mm | +/- 0.001 in. |

| Shaft diameters | +/- 0.025 mm | +/- 0.001 in. |

| Edge Condition | Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. |

| Threads and Tapped Holes | Standard size: Diameter: standard drill bit sizes; depth: 4×diameter |

| Maximum size: Diameter: Φ 1 mm; depth: 10×diameter |

| We can produce threads of any specification and size required by our customers. |

| Text | We can use CNC engraving or laser carving to create standard text based on customers' requirements. |

| For plastic and soft materials: minimum width of 0.457 mm, depth of 0.3 mm | For plastic and soft materials: minimum width of 0.018 in., depth of 0.011 inch |

| For hard material: minimum width of 0.838 mm, depth of 0.3 mm | For hard material: minimum width of 0.033 in., depth of 0.011 inch |