CNC turning, a process in which a computer-controlled lathe is used to shape materials into precise cylindrical parts, offers numerous benefits over traditional manual turning methods. Here are some key advantages:

1. High Precision and Accuracy: CNC turning machines are capable of producing parts with extremely tight tolerances and high precision. This accuracy is maintained consistently across multiple parts, ensuring uniformity and reducing errors.

2. Increased Productivity and Efficiency: CNC turning can operate continuously and at high speeds, significantly increasing production rates. The automated nature of CNC machines allows for faster cycle times and the ability to run unattended for extended periods.

3. Consistency and Repeatability: Once a program is set up and tested, CNC turning machines can produce identical parts repeatedly with minimal variation, ensuring consistent quality and reducing waste.

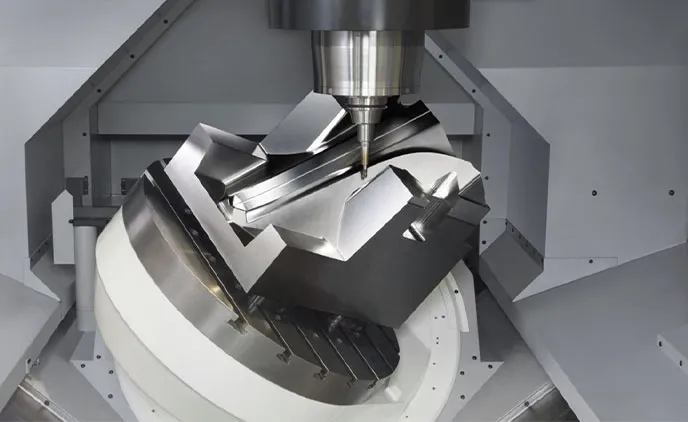

4. Complex Geometries: CNC turning can handle complex geometries and intricate designs that would be difficult or impossible to achieve manually. This capability allows for the production of sophisticated and highly detailed parts.

5. Reduced Setup Time: CNC machines often have quick-change tooling systems and automated setup features, reducing the time required to prepare the machine for a new job. This efficiency leads to shorter lead times and faster turnaround.

6. Flexibility: CNC turning machines can be easily reprogrammed to produce different parts, allowing for flexibility in production. This adaptability is particularly useful for small batch production and custom orders.

7. Improved Safety: The automation of CNC turning reduces the need for manual intervention, which minimizes the risk of accidents and injuries. Operators can monitor the process from a safe distance.

8. Lower Labor Costs: CNC turning reduces the need for skilled manual labor, as the machines are programmed and operated by fewer technicians. This can lead to significant cost savings in labor.

9. Enhanced Material Utilization: CNC turning machines optimize the use of raw materials, reducing waste and improving material efficiency. This can result in cost savings and a more sustainable production process.

10. Versatility in Material Handling: CNC turning can work with a wide variety of materials, including metals (such as aluminum, steel, and titanium), plastics, and composites, making it suitable for diverse applications across multiple industries.

11. Integration with Other Processes: CNC turning machines can be integrated with other CNC processes (such as milling, drilling, and grinding) to create multifunctional machining centers, further enhancing productivity and capabilities.

12. Ease of Modifying Designs: Changes to part designs can be easily implemented by updating the CNC program, allowing for quick adjustments without extensive downtime or retooling.

These benefits make CNC turning a highly efficient, reliable, and versatile manufacturing process, suitable for a wide range of applications from prototyping to mass production.