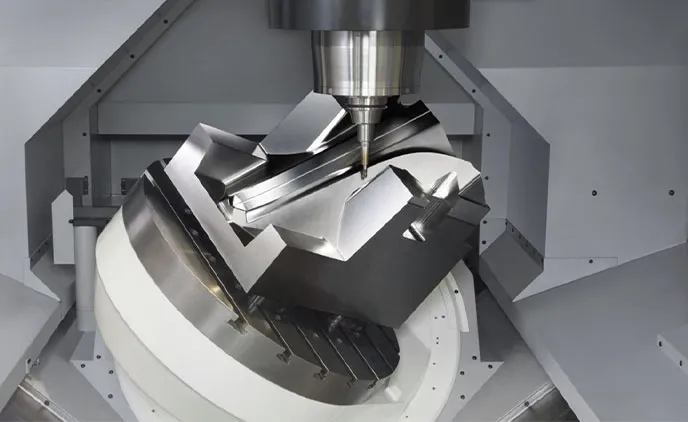

5-axis CNC machining is an advanced form of computer numerical control (CNC) machining that enables the movement of a tool or a workpiece along five different axes simultaneously. This capability allows for the creation of complex and intricate parts with high precision and efficiency. Here are the key aspects and benefits of 5-axis CNC machining:

Key Aspects of 5-Axis CNC Machining:

1. Axes Movement:

- X, Y, and Z Axes: These are the standard linear axes found in 3-axis CNC machining, moving left-right (X), forward-backward (Y), and up-down (Z).

- Rotational Axes (A and B): In addition to the three linear axes, 5-axis machines have two additional rotational axes. These can rotate around the X-axis (A axis) and the Y-axis (B axis), or around other configurations depending on the machine setup.

2. Simultaneous Movement:

- All five axes can move simultaneously, allowing for the machining of complex geometries and surfaces that would be difficult or impossible with fewer axes.

Benefits of 5-Axis CNC Machining:

1. Complex Geometry:

- The ability to approach the workpiece from any direction makes it possible to create intricate and complex shapes, undercuts, and deep cavities that are not feasible with 3-axis or even 4-axis machining.

2. Improved Surface Finish and Accuracy:

- By using shorter cutting tools and positioning them optimally, 5-axis machining reduces vibrations and deflections, leading to better surface finishes and higher accuracy.

3. Reduced Setup Time:

- 5-axis machining often eliminates the need for multiple setups and repositioning of the workpiece. This not only saves time but also reduces the potential for errors.

4. Enhanced Tool Life:

- Optimal tool orientation throughout the machining process reduces wear and tear on the cutting tools, extending their lifespan and reducing tool costs.

5. Efficiency and Speed:

- The simultaneous movement of multiple axes can significantly increase the speed of the machining process, improving overall production efficiency.

6. Flexibility and Versatility:

- 5-axis machines can handle a wide range of materials and part sizes, making them suitable for various industries including aerospace, automotive, medical, and more.

7. Reduced Cost and Waste:

- By enabling more precise material removal and reducing the need for additional setups, 5-axis machining can lower overall production costs and minimize material waste.

Applications of 5-Axis CNC Machining:

1. Aerospace: Manufacturing of complex components such as turbine blades, structural parts, and aerodynamic surfaces.

2. Automotive: Production of intricate parts like engine components, transmission parts, and custom designs.

3. Medical: Creation of medical devices, implants, and surgical instruments with complex shapes and tight tolerances.

4. Energy: Machining of components for wind turbines, gas turbines, and other energy systems.

5. Prototyping: Rapid prototyping of complex parts and designs for various industries.

Types of 5-Axis Machines:

1. Trunnion Style: The table or workpiece is mounted on a trunnion that rotates along the A and C axes.

2. Swivel Head Style: The cutting tool or spindle head rotates along the B and C axes, while the workpiece remains stationary.

3. Combination Style: Some machines combine both trunnion and swivel head movements for added flexibility.

Overall, 5-axis CNC machining represents a significant advancement in manufacturing technology, enabling the production of highly complex and precise components with increased efficiency and reduced lead times.