What is knurling? The basics of knurling

Ⅰ Introduction to knurling

Knurling process is a processing process in which a specific pattern or pattern is pressed out on the surface of metal or non-metal materials by rolling tools (knurling wheel or knurling knife). This process can not only beautify the appearance of the product, but also enhance the grip of the parts, anti-slip and anti-loose performance, widely used in machinery, automobiles, home appliances, electronics, instrumentation and other fields.

Ⅱ Knurling process type

Knurling process according to the different processing methods, mainly divided into the following categories:

1.Linear knurling: The use of linear knurling wheels to press a linear texture on the surface of parts, commonly seen in handles, knobs and other parts.

2.Mesh knurling: Through the combination of different angles of knurling wheel to form a grid texture, improve the anti-slip effect, common in tool handles and parts requiring high friction coefficient.

3.Diamond knurling: The use of a knurling wheel of a specific shape to form a diamond or similar pattern on the surface, often used in precision instruments or highly decorative products.

4.Custom knurling: According to customer needs, design and manufacture knurling wheels with specific shapes and patterns to achieve personalized customization.

Ⅲ Knurling process flow

1.Preparation material: Select the appropriate metal material as the base material, such as steel, aluminum, copper, etc.

2.Design pattern: According to the requirements of the design of the required knurled pattern, such as straight, mesh, twill, etc.

3.Making rollers: Making special knurled rollers according to the designed pattern.

4.Pretreatment: necessary pretreatment of the workpiece, such as removing oil, grinding, etc.

5.Rolling operation:

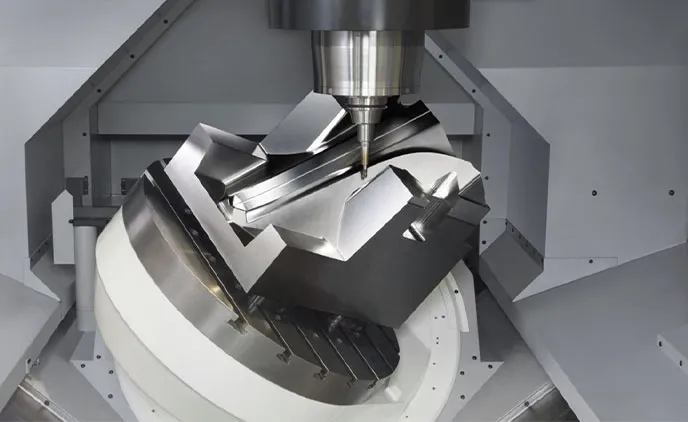

Fix the workpiece to the machine tool or special knurling machine.

Adjust the contact pressure and feed speed between the roller and the workpiece.

Start rolling, through the roller to apply enough pressure to the surface of the workpiece, so that it produces plastic deformation to form the required pattern.

6.Check quality: After knurling is completed, check whether the surface quality and dimensional accuracy meet the requirements.

7.Follow-up treatment: If you need to further improve the wear resistance or corrosion resistance, you can carry out post-treatment processes such as deburring, heat treatment, electroplating, etc.

Ⅳ Key points of knurled technique

Preparation stage: Select the appropriate knurling wheel, adjust the parameters of the lathe or knurling machine (such as speed, feed).

Workpiece clamping: Ensure that the workpiece is firmly installed on the fixture to avoid movement or vibration during processing.

Processing process: Slowly and evenly feed the knurling wheel, pay attention to control the pressure, to avoid excessive embossing resulting in material deformation or damage.

Quality check: After machining, use measuring tools to check dimensional accuracy and texture quality, and fine-tune if necessary.

Ⅴ Knurling material selection

Knurled processes are suitable for a variety of materials, including but not limited to.

Metals: such as copper, aluminum, stainless steel, alloy steel, etc., with good machinability and mechanical properties.

Plastics: such as ABS, nylon, polycarbonate, etc., through appropriate knurling wheel design and processing parameter adjustment, you can also obtain good knurling effect.

Soft materials: Some rubber and silicone materials can also be knurled, but attention should be paid to controlling the processing pressure and speed to avoid material deformation.

Ⅵ Knurling advantage

1.Enhanced utility

Non-slip: Knurled process can form a certain texture on the surface of metal products, thereby significantly increasing its friction, effectively preventing sliding or slipping, and improving the safety and stability of use.

Durability: The raised and sunken structure formed on the knurled surface helps disperse and resist wear, extending the service life of metal products. At the same time, this texture can also reduce the damage of external factors on the surface of the product to a certain extent.

2.Enhance aesthetics

Decorative effect: knurled process can create a variety of patterns and textures, such as straight, mesh, diamond, diamond shape, etc. These patterns are not only beautiful and generous, but also can be customized according to demand to meet the aesthetic needs of different scenes and products.

Improve the texture: the surface texture of the metal products after knurling is richer, has a stronger visual impact, and can improve the overall grade and quality of the product.

3.Improve functionality

Increased surface area: Knurled process can increase the surface area of metal products, which is especially important for products requiring increased paint adhesion or other surface treatments. A larger surface area means stronger adhesion, helping to improve the durability and aesthetics of the product.

Easy to hold: The surface of the metal product after knurling is rougher, which helps to increase the friction between the hand and the product, making it more stable and reliable in the process of holding and using.

4.Technological advantage

High processing efficiency: knurled process usually adopts mechanized production mode, which can achieve rapid and mass production and improve production efficiency.

Wide range of application: knurled process is suitable for a variety of materials and shapes of the product processing.

Cost-effective: Compared with other surface treatment methods, knurling process requires simple equipment, convenient operation, high production efficiency, so the overall cost is relatively low.

5.Environmental advantage

Non-polluting: As a cold processing technology, the knurling process does not require the use of chemical reagents, nor does it produce harmful gases or waste liquid emissions.

Energy saving and consumption reduction: less energy consumption in the processing process, in line with the current development trend of green environmental protection.

Ⅶ Knurling application

Manufacturing: Production of tool handles, automatic pencils, pistol grips, barbell bars and other products.

Automotive industry: automotive interior parts, steering wheels, pedals, etc.

Medical field: Production of surgical instruments.

Decoration industry: for furniture, doors and Windows and other surface decoration treatment, metal crafts, MEDALS and so on

Household items: kitchen utensils, furniture handles, etc.

Material processing: Achieve texture effect on ceramic, glass, wood and other materials.

Hong Zhong Xin's high quality surface finishing services

Hong Zhong Xin has many years of experience in providing cost effective surface treatment solutions for various industries and we offer a wide range of materials and finishes. Our team of experts works with you to create custom metal finishing programs, so you can be sure to receive a high quality service that meets all your unique needs.

If you have any production needs, please contact us for a free quote, please click "Contact us".