What is pickling? Definition, classification, process, advantages, applications of pickling

Ⅰ Introduction to pickling

Pickling process is a widely used in metal surface treatment process, its main purpose is to remove oxides, rust, welding stains and other pollutants on the metal surface through the corrosion of acid solution, in order to improve the quality of the metal and prepare for subsequent treatment steps. Pickling is widely used in the surface treatment of steel, stainless steel, copper, aluminum and other metal materials, as well as parts processing and manufacturing in chemical, machinery, automotive, aerospace and other fields. The basic principle of pickling is to use acidic chemicals to chemically react with impurities on the surface of the metal to generate soluble compounds, and then dissolve and remove these impurities.

Ⅱ Pickling classification

Classification by type of acid:

1.Sulfuric acid pickling

Features: Sulfuric acid is a strong acid, with strong oxidation and dehydration. Sulfuric acid pickling can effectively remove the oxide and rust on the surface of steel, but the corrosion of metal is also large.

Application: It is often used for pickling of iron and steel materials, especially for thick oxide skin and severely rusted workpieces. However, attention should be paid to controlling the concentration and temperature of sulfuric acid in the pickling process to avoid excessive corrosion.

2.Hydrochloric acid pickling

Features: Hydrochloric acid is also a strong acid, with good solubility and volatility. Hydrochloric acid pickling speed is fast, the corrosion of metal is relatively small, but it is easy to produce acid fog, which has a certain impact on the environment and human health.

Application: Suitable for pickling all kinds of metal materials, especially for stainless steel, copper, aluminum and other non-ferrous metals pickling effect is good. When using hydrochloric acid pickling, it is necessary to take effective ventilation measures to reduce the production of acid fog.

3.Nitric acid pickling

Features: Nitric acid is a strong oxidizing acid, has a strong corrosive. Nitric acid pickling can quickly remove the oxide and rust on the metal surface, but it is more corrosive to the metal, and it is easy to cause excessive corrosion on the metal surface.

Application: Generally used for pickling of special materials such as stainless steel and titanium alloy, or in the case of rapid removal of oxide skin. Due to the greater danger of nitric acid, special care should be taken when using it.

4.Phosphate pickling

Features: Phosphoric acid is a medium strong acid, with weak corrosion and better corrosion inhibition properties. Phosphoric acid pickling can remove the oxide and rust on the surface of the metal, while the corrosion of the metal is less, suitable for precision parts and high surface quality requirements of the workpiece pickling.

Application: Often used in electronic, aerospace and other fields of metal parts pickling.

5.Mixed acid acid pickling

Features: The mixed use of two or more kinds of acids can comprehensively utilize the advantages of various acids to improve the pickling effect. For example, the mixed acid of sulfuric and hydrochloric acid can improve the pickling speed and the ability to remove the oxide skin; The mixed acid of nitric acid and hydrofluoric acid can be used for pickling stainless steel to improve the pickling effect.

Application: According to different pickling requirements and metal materials, choose the right mixed acid for pickling.

Ⅲ Pickling process

1.pretreatment

Cleaning: Before pickling, the metal surface needs to be pre-cleaned to remove non-oxidizing impurities such as oil and dust. This is usually achieved by lye cleaning, sandblasting, or other physical methods.

Degreasing: Removal of grease and other organic contaminants from metal surfaces, either by immersion in alkaline solutions or by steam degreasing.

2.pickling

Dipping: Placing pre-treated metal in an acid bath. The concentration and temperature of the acid bath should be adjusted according to the type of metal and the surface condition.

Reaction time: The time the metal stays in the acid bath depends on the thickness of the surface oxide and the concentration and temperature of the acid used.

Stirring: In order to accelerate the contact between the acid and the metal surface, mechanical stirring or bubble stirring can be used to ensure that the acid solution is in full contact with the metal surface.

3.Postprocessing

Neutralization: After pickling, the metal surface needs to be neutralized with an alkaline solution to prevent further corrosion of the metal.

Rinse: Rinse the metal surface thoroughly with clean water to remove residual acid and dissolved oxides.

Drying: Finally, the metal needs to be dried to prevent moisture residue from causing new rust to form. Drying can be achieved by natural drying, compressed air drying or drying.

Ⅳ Pickling advantage

1.Efficient removal of oxide and rust

Quick surface cleaning: pickling can quickly dissolve the oxide and rust on the metal surface, so that the metal is restored to a clean state. For example, in the process of steel production, the surface of the steel after hot rolling will form a thick layer of oxide, which can be removed in a short time by pickling, ready for subsequent processing and use.

Thorough removal: Pickling can penetrate into the tiny pores and crevices on the metal surface to completely remove the oxide and rust hidden in them. This is very important for some applications that require high surface quality, such as precision machinery parts, automotive parts, etc.

2.Improve metal surface quality

Forming a uniform surface: The metal surface after pickling is more uniform and smooth, which is conducive to subsequent processing and painting. For example, during electroplating, pickling can remove impurities and oxides from the surface of the metal, making the coating more solid and uniform.

Enhance adhesion: pickling can remove oil and impurities on the metal surface, improve the adhesion of coating, coating, etc., and the metal surface. This can extend the service life of the coating and coating and improve the quality and reliability of the product.

3.Improve metal workability

Reduce hardness: For some metal materials with higher hardness, pickling can reduce its hardness to a certain extent, making it easier to carry out machining operations such as cutting and stamping. For example, after pickling high carbon steel, the hardness will be reduced and the processing performance will be improved.

Improve plasticity: Pickling can eliminate the stress generated by metal materials in the process of processing, improve its plasticity and toughness. This is very important for some metal materials that need to be cold worked, such as aluminum plates and copper plates.

4.The cost is relatively low

Simple equipment: The equipment required for pickling is relatively simple, mainly including pickling tank, acid circulation system, heating device, etc. Compared with other surface treatment methods, the investment cost of pickling equipment is lower.

Easy operation: The operation process of pickling is relatively simple, only need to soak the metal material in the acid or pickling by spraying. The operator can master the operation method of pickling after simple training.

5.Strong adaptability

Suitable for a variety of metal materials: pickling can be used for steel, stainless steel, copper, aluminum and other metal materials surface treatment. Different metal materials can choose different pickling liquid and pickling process to achieve the best treatment effect.

Workpieces of different shapes and sizes can be processed: pickling can be applied to metal workpieces of various shapes and sizes, whether it is a large steel structure or a small precision part, it can be effectively treated by pickling.

Ⅴ Matters needing attention

Control the concentration and temperature of pickling solution: according to different metal materials and pickling requirements, choose the appropriate concentration and temperature of pickling solution to ensure the pickling effect and metal surface quality.

Control pickling time: too long pickling time may lead to excessive corrosion of metal surface, affecting dimensional accuracy and surface quality; If the pickling time is too short, it may not be able to completely remove the oxide and rust. Therefore, it is necessary to control the pickling time according to the actual situation.

Add corrosion inhibitor: In order to reduce the corrosion of the acid on the metal, it is necessary to add an appropriate amount of corrosion inhibitor in the acid wash solution. Corrosion inhibitors can form a protective film on the surface of the metal to prevent direct contact between the acid and the metal, thereby reducing corrosion.

Pay attention to safety protection: pickling liquid is highly corrosive. Pay attention to safety protection during operation. Wear protective equipment, such as gloves, goggles, and protective clothing. At the same time, it is necessary to operate in a well-ventilated environment to avoid harm to the human body caused by acid fog.

Cleaning and drying: After pickling, the metal surface needs to be thoroughly cleaned with clean water to remove residual pickling liquid and corrosion products. Then, it is necessary to dry the metal surface to avoid moisture residue causing rust on the metal surface.

Ⅵ Pickling application

Iron and steel industry

Plate treatment: Pickling is an important part of the steel plate production process, which is used to remove the oxidation scale on the surface of the hot rolled steel plate, and prepare for the subsequent cold rolling, coating, stamping and other processes.

Steel pipe production: In the process of steel pipe manufacturing, pickling can remove the oxide on the inside and outside surface of the steel pipe and improve the surface quality of the steel pipe.

Cold rolled strip: The cold rolled strip needs to be pickled before entering the cold mill to remove the surface oxide layer and ensure the finished surface finish.

Automobile industry

Body parts: Many parts of the car body need to be pickled to remove the oxide layer on the surface, improve the adhesion of the coating, and enhance the anti-corrosion performance.

Stamping parts: Before stamping forming, sheet metal usually needs to be pickled to ensure the surface quality after forming.

Metal processing industry

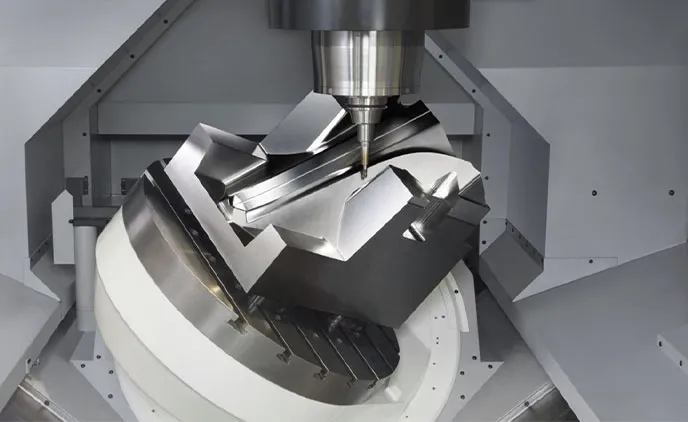

Pre-cutting treatment: Before laser cutting or plasma cutting, metal sheets often need to be pickled to remove surface oxides and ensure that the cutting edge is smooth and smooth.

Pre-welding treatment: the metal surface must be clean before welding, pickling can remove the oxide and improve the quality of welding.

Hardware manufacturing

Fasteners: bolts, nuts and other fasteners need to be pickled before electroplating to remove the surface oxide layer and ensure uniform adhesion of the plating layer.

Door and window hardware: door handles, hinges and other hardware need to be pickled before surface treatment (such as chrome plating, painting) to improve the surface finish and beauty.

Household appliance manufacturing industry

Housing of household appliances: The housing of household appliances such as refrigerators and washing machines needs to be pickled before painting to remove the oxidation layer on the surface and ensure the firmness of the coating.

Kitchen appliances: The internal components of kitchen appliances such as ovens and microwave ovens need to be acid-washed to remove surface oxides and improve corrosion resistance.

Construction industry

Steel structure: The steel structure used in construction needs to be pickled before painting to remove the oxidation layer on the surface and enhance the corrosion resistance.

Curtain wall material: The metal frame of the glass curtain wall needs to be pickled before installation to ensure the cleanliness of the surface and improve the aesthetics and service life.

Aerospace industry

Aircraft parts: Some parts of aircraft require pickling during the manufacturing process to remove the surface oxide layer and improve the surface finish and corrosion resistance.

Rocket components: Some components of rockets also require pickling during the manufacturing process to ensure surface cleanliness and corrosion resistance.

Electronics industry

Printed circuit board: In the PCB production process, some steps require pickling to remove surface oxides to ensure the reliability of circuit connections.

Metal housing: The metal housing of electronic devices needs to be pickled before surface treatment to improve the surface finish and aesthetics.

Hong Zhong Xin's high quality surface finishing services

Hong Zhong Xin has many years of experience in providing cost effective surface treatment solutions for various industries and we offer a wide range of materials and finishes. Our team of experts works with you to create custom metal finishing programs, so you can be sure to receive a high quality service that meets all your unique needs.

If you have any production needs, please contact us for a free quote, please click "Contact us".