What is polishing? Principle, classification, process, application

Ⅰ Introduction to polishing

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the workpiece in order to obtain a bright, flat surface processing method.

Polishing cannot improve the dimensional accuracy or geometric shape accuracy of the workpiece, but for the purpose of obtaining a smooth surface or mirror luster, and sometimes to eliminate the luster (extinction), usually with a polishing wheel as a polishing tool.

Ⅱ Polishing classification

1.Mechanical polishing

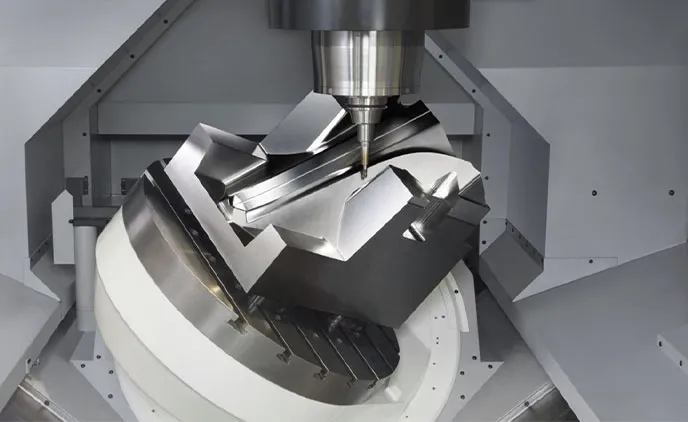

Mechanical polishing is one of the most traditional and widely used polishing methods. It uses abrasive materials (such as grinding wheels, sand belts, polishing cloth wheels, etc.) to carry out high-speed friction with the workpiece surface, and gradually reduce the roughness of the workpiece surface by constantly replacing finer abrasive materials until the required finish is reached. Mechanical polishing is suitable for most metal materials and some non-metallic materials, but attention should be paid to control the strength and temperature to avoid surface burns or deformation caused by excessive polishing.

Its advantages are low cost and simple operation; The disadvantages are low efficiency, uneven polishing surface, difficult to master polishing time, suitable for small area surface treatment; Mechanical polishing can make the metal surface roughness value Ra=0.3~3.0μm.

2.Chemical polishing

Chemical polishing through chemical solution and the workpiece surface chemical reaction, dissolve and remove the surface of the microscopic unevenness and oxides, to achieve smooth effect. This method does not require complex equipment, is simple to operate, and is suitable for surface treatment of complex shape workpieces. However, attention should be paid to the treatment of chemical waste liquid to prevent environmental pollution.

Its advantage is that the equipment is simple and the surface roughness of the machined parts is uniform; The operation is simple, and many workpieces can be polished simultaneously; High efficiency, and can be polished complex shape of the workpiece.

The disadvantage is that the adjustment and regeneration of the solution used in chemical polishing is more difficult, and the application is limited, and in the chemical polishing process, nitric acid emits a large number of yellow and brown harmful gases, which is very serious to the environmental pollution. The surface roughness obtained by chemical polishing is generally tens of μm.

3.Electrolytic polishing

Electrolytic polishing is in the electrolytic cell, the use of electrochemical principle, through anodic oxidation to remove the surface of the workpiece micro-convex part to achieve smooth and bright effect. Electrolytic polishing has high efficiency, can handle large area and complex shape of the workpiece, and the surface uniformity after polishing is good, but the equipment cost is high, and the electrolytic parameters need to be strictly controlled to avoid excessive corrosion.

Its advantages are:

The internal and external color is consistent, the luster is durable, can process hard materials, soft materials and thin-walled, complex shape, small parts and products.

The amount of polishing is very small, and the dimensional accuracy and shape accuracy after polishing can be controlled within 0.01mm.

High polishing rate, polishing speed is not affected by the hardness of the material.

Simple process, easy operation, simple equipment, small investment.

The disadvantages are:

The application range of electrolytic polishing is limited due to the complexity of pre-polishing treatment, the poor versatility of electrolyte, short service life, strong corrosion and difficult to handle, etc.

It is impossible to eliminate the "thick ripple" on the original surface, and the matrix roughness of the workpiece surface is required, which should generally be below Ra1.6.

4.Nano-polishing

Nano polishing is called plasma nano polishing, carried out in a special automatic control equipment, plasma is at high temperature and high pressure, the polishing agent is water-soluble, but at high temperature and high pressure, electrons will escape from the nucleus and run out, the nucleus forms a positively charged ion, when these ions reach a certain number can become a plasma state, plasma state energy is very large. When this plasma is rubbed with the object to be polished, it will instantly make the object reach the effect of surface brightness.

Advantages:

Nano polishing has low processing cost, is conducive to popularization, and has no pollution to the processing environment.

Simple and easy, the use of special automatic control equipment, reduce labor costs.

High efficiency, good effect, high precision control, small size impact, usually can be controlled at 0.1μm/min, uniform polishing, so that the entire workpiece surface and dead Angle parts can achieve a consistent mirror effect.

Wide range of applications, plasma nano polishing can be applied to mobile phone electronics, integrated circuit manufacturing, sports equipment (golf), glasses manufacturing, medical equipment, watch accessories, auto parts, LED manufacturing process, digital accessories, aerospace and other industries.

5.Ultrasonic polishing

Ultrasonic polishing uses the cavitation effect and impact effect generated by ultrasonic vibration in the liquid medium to make the abrasive particles suspended in the liquid constantly impact the surface of the workpiece, so as to achieve polishing. This method is suitable for the polishing of precision parts and small holes.

Advantages:

It has the advantages of high efficiency, fine and no pollution.

Suitable for processing hard and brittle materials and non-conductive non-metallic materials.

The tool has little effect on the force and heat of the workpiece, and does not produce deformation, burn and metamorphic layer.

The machining accuracy is 0.01-0.02mm, and the roughness is 1-0.1μm.

Can polish thin-wall, wafer, narrow slit and low-stiffness parts; The equipment is simple, easy to use and maintain.

6.Magnetorheological polishing

Magnetic fluid polishing technology is a new advanced processing technology, magnetic particles, surfactants, and some other additives in accordance with a certain proportion of dispersed in the base liquid to form a suspension, when the magnetic field is applied, the magnetic particles into chain or fibrous arrangement, resulting in an increase in the viscosity of the entire fluid, showing solid-like characteristics; When the magnetic field disappears, the magnetic particles return to the original dispersed free state, the entire system returns to the fluid state, and the process of "liquid-solid transformation" can be completed in milliseconds. When a certain amount of abrasive particles is added to the fluid, the magnetorheological fluid has the effect of grinding and polishing. Different base load fluid and abrasive particles can be selected according to the different polishing objects.

Features:

Can achieve very low roughness, generally used for polishing precision optical lenses.

Since the whole workpiece is in the liquid, the polishing heat is easy to disperse, and it will not cause overheating in the local position of the workpiece, which is conducive to avoiding the polishing of orange peel.

All parts of the workpiece are in uniform contact with the fluid, which can ensure that the polishing effect is uniform and not limited by the shape of the workpiece.

Ⅲ Polishing process

The polishing process generally includes pre-treatment (such as cleaning, oil removal, rust removal), rough polishing (to remove large areas of unevenness), fine polishing (to refine the surface), polishing (to achieve the final finish), inspection (to evaluate the polishing quality) and post-treatment (such as cleaning, drying, protective treatment) steps. The process can be adjusted according to material characteristics and polishing requirements.

Ⅳ Polishing advantage

Polished surfaces prevent rust and corrosion.

Polished parts are easier to clean and maintain. In addition, they are less likely to harbor dirt, grime, and bacteria.

Minimizes surface degradation and increases the durability of parts and products.

Polishing can eliminate microscopic roughness and reduce surface friction, which is beneficial for parts that move or slide against each other.

The polishing method is a solid basis for further surface treatment, such as spray painting or coating.

The surface polishing of metal parts produces a shiny mirror effect that significantly enhances visual appeal.

Ⅴ Polishing defect

This process is time-consuming for complex components.

Polishing complex parts, such as complex mechanical parts, can be time-consuming and affect production schedules.

Due to repeated surface treatments using abrasives of different sizes, polishing can be more expensive than other finishing processes.

Achieving a uniform finish requires a professional to handle the project.

Improper use of polish may produce microscratches.

Ⅵ Polishing application

| Automotive industry | wheels, bumpers, exhaust pipes, decorative parts, engine parts, etc |

| Aerospace components | turbine blades, engine parts, fuselage trim, cockpit instruments. |

| Medical industry | Surgical instruments, implants, prosthetics and medical tools. |

| Electronics | smartphone casings, laptop hinges, camera parts, etc |

| Jewelry | Enhance the gloss and beauty of metal jewelry and precious stones. |

| Optical industry | Manufacturing lenses, prisms and other optical components to achieve high precision mirror effect. |

| Marine equipment | deck fittings, hull decorations, anchor chains, navigation tools, etc. |

Ending

Polishing brings out the gloss of the surface of the product, improving the quality and performance of such products in many different ways. It is widely used in automotive, construction, aerospace and various other industrial applications.

Hong Zhong Xin's high quality surface finishing services

Hong Zhong Xin has many years of experience in providing cost effective surface treatment solutions for various industries and we offer a wide range of materials and finishes. Our team of experts works with you to create custom metal finishing programs, so you can be sure to receive a high quality service that meets all your unique needs.

If you have any production needs, please contact us for a free quote, please click "Contact us".