What is sand blasting?Basic knowledge

Ⅰ Introduction to sand blasting

The basic principle of the sandblasting process is to use compressed air (or water) as a power source, and the abrasive (such as quartz sand, glass beads, steel balls, etc.) is sprayed to the surface of the workpiece to be treated through a special nozzle at high speed. In this process, abrasive particles and the workpiece surface impact, cutting and extrusion, thereby stripping the surface of the oxide, rust layer, dirt and old coating, while forming a new microscopic rough surface. This rough surface helps to enhance the adhesion of the coating, improving the beauty and durability of the product.

Ⅱ Classification of sandblasting process

The sandblasting process can be classified according to different classification criteria:

By power source: dry sandblasting (using compressed air) and wet sandblasting (using a mixture of water and abrasive).

According to the mode of operation: manual sandblasting automatic sandblasting and robot sandblasting

Divided by treatment effect: coarse sandblasting (for deep cleaning and removal of old coatings), fine sandblasting (for surface beautification and refinement of roughness)

Ⅲ Abrasive selection

The choice of abrasive is the key link in the sandblasting process, which directly affects the treatment effect, the quality of the workpiece and the subsequent treatment process. Common abrasives include:

Quartz sand: low cost, suitable for general cleaning and rust removal.

Glass beads: The surface is smooth, the surface damage to the workpiece is small, often used in the surface treatment and beautification of precision parts.

Steel shot: high hardness, suitable for removing heavy rust and old coating, can also be used for surface strengthening treatment.

Alumina: Suitable for stainless steel, aluminum and other light metal surface treatment, can effectively avoid surface scratches.

The choice of abrasive should be determined according to many factors such as workpiece material, processing requirements and cost considerations.

Ⅳ Blasting specification

| Item | information |

| Materials | ABS, Aluminum, Brass, Stainless Steel, Steel |

| Color | n/a |

| Texture | Matte |

| Standards | #120, #150, #180, #200, #220 |

Ⅴ The main application of sand blasting

1.Processing before coating and bonding of workpiece

Sandblasting can remove all dirt such as rust on the surface of the workpiece, and establish a very important basic pattern on the surface of the workpiece (that is, the commonly called rough surface), and can achieve different degrees of roughness by replacing abrasive with different particle sizes, greatly improving the binding force of the workpiece and coating and plating. Or make the adhesive bonding stronger and better quality.

2.Cleaning and polishing of the rough surface of the cast and forged parts and the workpiece after heat treatment

Sandblasting can clean up all the dirt on the surface of the workpiece after casting and forging and heat treatment (such as oxide, oil and other residues), and polish the surface of the workpiece to improve the finish of the workpiece, and play a role in beautifying the workpiece. Sandblasting can make the workpiece show uniform metal color, make the workpiece appearance more beautiful, to beautify the role of decoration.

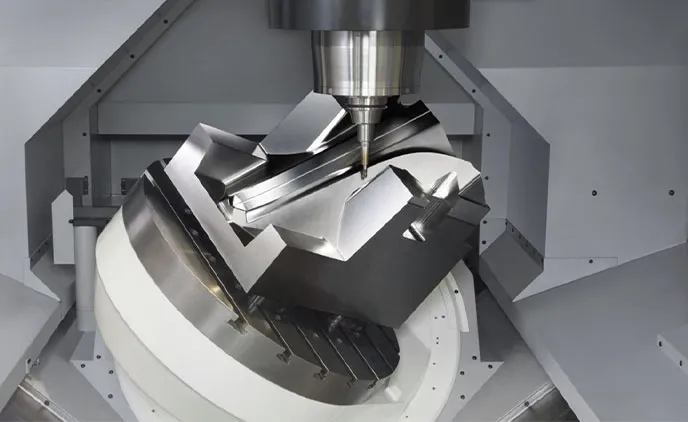

3.Machining burr cleaning and surface beautification

Sand blasting can clean the small burrs on the surface of the workpiece, and make the surface of the workpiece more flat, eliminate the harm of the burr, and improve the grade of the workpiece. And sandblasting can make a small rounded corner at the junction of the workpiece surface, so that the workpiece appears more beautiful and more precise.

4.Improve the mechanical properties of parts

After the mechanical parts are sandblasted, a uniform fine concave and convex surface (basic pattern) can be produced on the surface of the parts, so that the lubricating oil can be stored, so that the lubrication conditions can be improved, and the noise can be reduced to improve the service life of the machinery.

5.The effect of lighting

The surface of various workpieces is polished to make the surface of the workpiece more beautiful. Make the workpiece to achieve smooth and non-reflective requirements, that is, to achieve a certain surface roughness.

Ⅵ Process condition

The successful implementation of the sandblasting process requires strict control of the following process conditions:

Abrasive particle size: Select the appropriate abrasive particle size according to the processing requirements

Pressure and flow: Adjust the pressure and flow of compressed air or water to control the intensity of sand blasting.

Blasting Angle and distance: Reasonable blasting Angle and distance can maximize the treatment effect and reduce workpiece damage.

Processing time: Set a reasonable processing time according to the material and expected effect of the workpiece.

Ⅶ Sand blasting precautions

Complex, fine and intricate geometries may be difficult to sandblast evenly.

Blasting is not recommended for thin walls, otherwise there is a risk of deformation.

Areas requiring strict precision (e.g. holes, cavities) need to be shielded before sandblasting

Hong Zhong Xin's high quality surface finishing services

Hong Zhong Xin has many years of experience in providing cost effective surface treatment solutions for various industries and we offer a wide range of materials and finishes. Our team of experts works with you to create custom metal finishing programs, so you can be sure to receive a high quality service that meets all your unique needs.

If you have any production needs, please contact us for a free quote, please click "Contact us".