What is spray paint? Definition, classification, process flow, advantages, applications

Ⅰ Introduction to painting

Spray painting is a method by which the paint is dispersed into uniform and fine droplets and applied to the surface of the workpiece with the help of air pressure, which can be divided into air spray painting, airless spray painting and electrostatic spray painting. Widely used in automobile, home, electronics, machinery and other industries.

Ⅱ Paint classification

It is mainly classified according to different spray methods of paint, mainly including:

1.Air spraying

The use of compressed air to spray paint on the surface of the workpiece after atomization, suitable for a variety of coatings and workpiece shapes.

2.Electrostatic spraying

A high-voltage electrostatic field is formed between the spray gun and the workpiece, so that the paint particles are charged and adsorbed on the surface of the workpiece, improving the utilization rate of the paint and the uniformity of the coating.

3.High pressure airless spraying

The paint is pressurized to extremely high pressure by a high pressure pump and sprayed directly from the nozzle to form a fine mist, suitable for high viscosity coatings and thick coating needs.

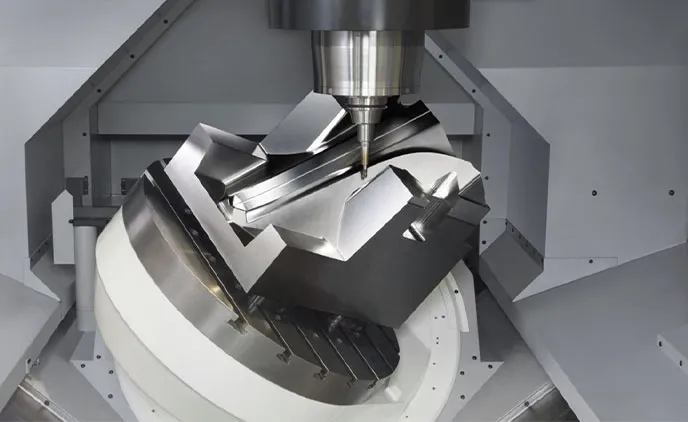

4.Automatic spraying robot

Combined with precision control system, precise spraying of complex shaped workpieces can improve production efficiency and quality consistency.

Ⅲ Spray painting process

1. Preparation

1.1 Obtaining Materials

Paint selection: Select the appropriate primer, medium coat, top coat and varnish according to the type of substrate, desired effect (e.g. gloss, color) and the environment in which it is used.

Auxiliary materials: diluent, curing agent, sandpaper, putty, polishing wax, etc.

Tools: spray gun, air compressor, blender, scraper, grinder, dust cloth, etc.

1.2 Surface Cleaning

Use degreaser to thoroughly remove grease, dirt and old coatings from the surface to be sprayed.

Rust removal. For metal surfaces, use sandpaper or a sandblaster to remove rust and oxide layers. After cleaning, ensure that the surface is dry and there is no moisture residue.

1.3 Environmental Control

Keep the paint area well ventilated to avoid dust and impurities

Control the temperature and humidity, the general temperature should be between 15°C and 30°C, humidity below 80%, to ensure that the paint dry normally.

2. Primer treatment

Evenly sprayed primer provides a good base for the upper coat and enhances adhesion. After the primer dries, it is lightly polished to remove surface defects such as orange peel lines and particles.

3. Fill in

Use putty or eye ash to fill surface defects such as dents, scratches, etc. Fill and sand several times until the surface is smooth and smooth.

4. Finish coating

Adjust top paint color as required to ensure accurate and consistent color. The use of wet to wet or multi-layer spraying technology, layer by layer coating coating between each layer need to wait for appropriate time to dry.

Pay attention to control the distance, speed and Angle of the spray gun to obtain a uniform smooth effect.

5. Varnish protection

After the finish is completely dry, varnish is applied to increase gloss and protect the finish from external erosion.

Varnish also needs to be evenly sprayed to avoid phenomena such as flow hanging and orange peel.

6. Polish and polish

Use sandpaper and polish of different thicknesses to remove blemishes from the spraying process and improve the smoothness of the finish.

Finally, the polishing machine and polishing wax are used for fine polishing, so that the paint has a mirror-like effect.

7. Quality inspection

Check the finish for chromatic aberration, run-off, scratches, orange peel and other defects.

Measure gloss and hardness to ensure compliance with standard requirements. Weather resistance tests are performed to assess the durability of finishes under different environmental conditions.

8. Post-maintenance

Clean regularly and avoid using aggressive cleaners. Avoid prolonged exposure to strong sunlight or extreme temperatures, and use scratch repair products for topical treatment if there are minor scratches.

Regular professional maintenance, such as waxing, sealing glaze, etc., to extend the life of the paint and maintain beauty.

Ⅳ Spray paint advantages

1. Aesthetic improvement

Spray paint can give the surface of the object a rich variety of colors and luster, improve the visual beauty of the product, to meet the needs of personalized or branding. By choosing different colors and finish effects (such as matte, glossy, metallic, etc.), you can make the product more attractive.

2. Strong weather resistance

high-quality spray paint has excellent weather resistance, can resist ultraviolet, wind and rain, frost and snow and other natural environment erosion, protect the surface of the object from damage, extend the service life of the product.

3. Anti-corrosion and anti-rust

Spray paint on the metal surface can form a dense protective layer, effectively isolate air and moisture, prevent metal rust and corrosion, which is particularly important for equipment that needs long-term exposure to outdoor environment.

4. Enhance hardness and wear resistance

After painting, the surface of the object will form a hard paint film, which can significantly improve the hardness and wear resistance of the surface, and reduce the damage caused by scratching and wear in daily use.

5. Improve the texture and feel

through the specific painting process and paint selection, you can achieve different touch and texture effects such as smooth, rough, matte or silky touch, improve the overall quality of the product.

6. Strong covering power

Spray paint has a good covering power, which can cover the defects, scratches or old colors on the surface of the object, and achieve the purpose of renovation or re-decoration.

7. Strong construction flexibility

spray painting can be flexibly constructed by spraying guns and other tools, whether it is a large area or a small area, plane or surface, can achieve uniform and rapid painting, improve construction efficiency.

8. Environmental performance

With the enhancement of environmental awareness, more and more spray paint uses environmentally friendly materials, such as water-based paint, low VOC(volatile organic compounds) paint, etc., reducing the harm to the environment and the human body.

Ⅴ Paint application

Automotive industry: Body painting, including primer, color paint, varnish and other multi-layer coating.

Home appliance industry: decoration and protection of shell and panel.

Furniture industry: wood, metal furniture surface treatment.

Machinery industry: equipment shell, parts of anti-rust and beautiful treatment.

Construction industry: anti-corrosion decoration of steel structure and aluminum profile.

Hong Zhong Xin's high quality surface finishing services

Hong Zhong Xin has many years of experience in providing cost effective surface treatment solutions for various industries and we offer a wide range of materials and finishes. Our team of experts works with you to create custom metal finishing programs, so you can be sure to receive a high quality service that meets all your unique needs.

If you have any production needs, please contact us for a free quote, please click "Contact us".