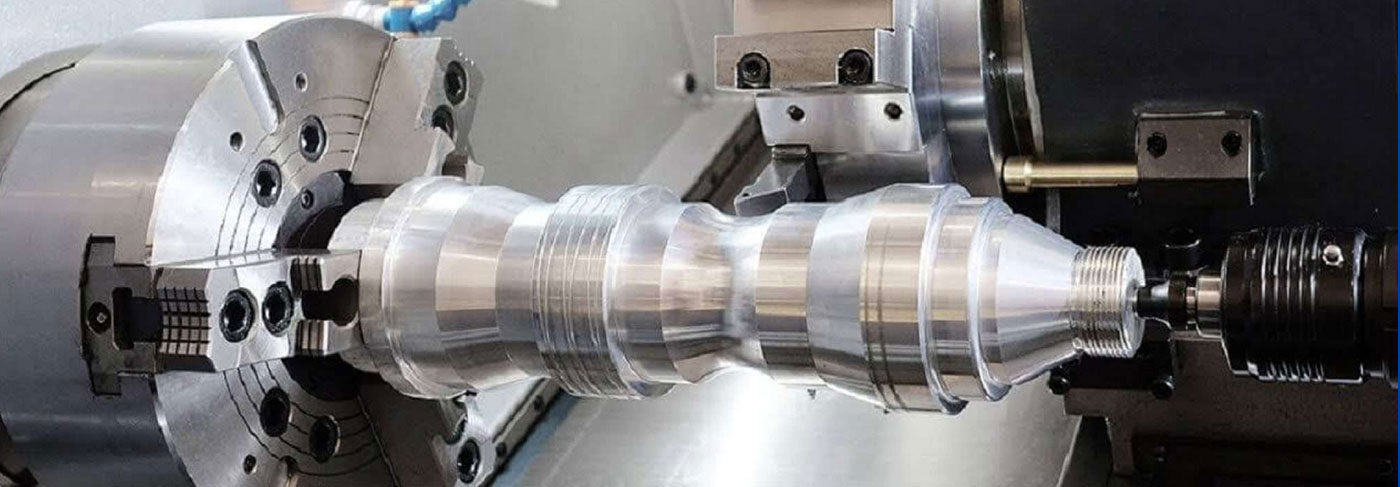

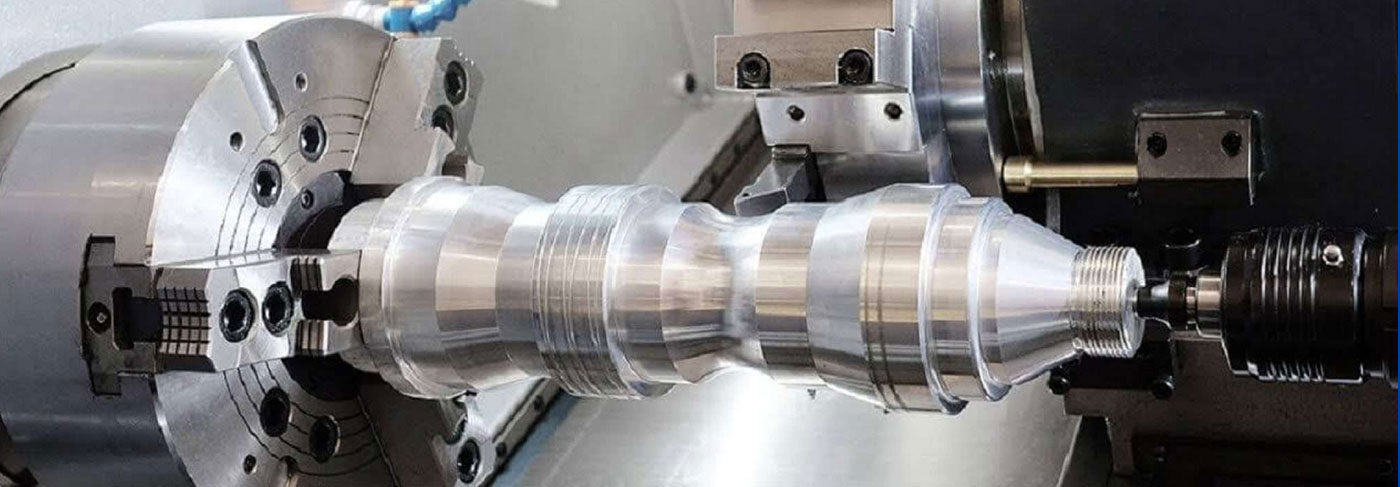

CNC Turning

CNC Turning service, also known as CNC lathes service, is a subtractive manufacturing process where metal round stock is held in a chuck on a spindle and rotated while a cutting tool is fed to the bar stock to remove material in order to create a part or product.We use CNC lathes with flexible tool features such as axial and radial holes, flats, grooves and other features that can be machined.

Our CNC Turning process can custom a wide variety of materials including aluminium, stainless steels and high performance plastics,Our CNC turning process can produces rapid prototypes and low-volume production parts that are as fast as 1 day.Contact us more details.

Suitable for CNC turning parts

1. Parts with high precision requirements

CNC lathes have good rigidity, high manufacturing and tool accuracy, and can easily and accurately carry out manual compensation and automatic compensation, so they can process parts with high dimensional accuracy.

2. A part having a cylindrical shape

Because the processing method of CNC lathe is to fix the material in the chuck and rotate the cutting, it is commonly used to process cylindrical parts.

3. A part with a complex outline

CNC lathes have linear interpolation and arc interpolation functions, and some CNC lathes even have some non-circular curve interpolation functions, so CNC lathes can turn parts composed of any plane curve contours, including parts of the list curve class that cannot be described by mathematical equations.

4. Rotary parts with special threads

CNC lathes can not only turn any straight, conical, inch threads with equal leads, but also can turn increased leads, reduced leads, and threads requiring smooth transition between equal leads and variable leads.

5. Hardened workpiece

In the large mold processing, there are many large size and complex shape parts, these parts after heat treatment deformation is large, grinding processing is difficult, at this time can use the ceramic turning tool on the CNC lathe to turn the hardened workpiece, to replace the grinding, improve the processing efficiency.

CNC turning materials

We have cited some commonly used processing materials, but it does not mean that we can only do these materials, as long as there are on the market, and you have the demand, we have the ability to process.

| Aluminum Machining | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. |

| Stainless Steel Machining | 55201, 55301, 55303, SS304, 55316, 55416, etc. |

| Steel Machining | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc. |

| Brass Machining | C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc. |

| Copper Machining | C11000, C12000, C12200, C10100, etc. |

| Iron Machining | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. |

| Plastic Machining | POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc. |