|

NAME |

DESCRIPTION |

MATERIALS |

COLOR |

TEXTURE |

LINK |

|

|

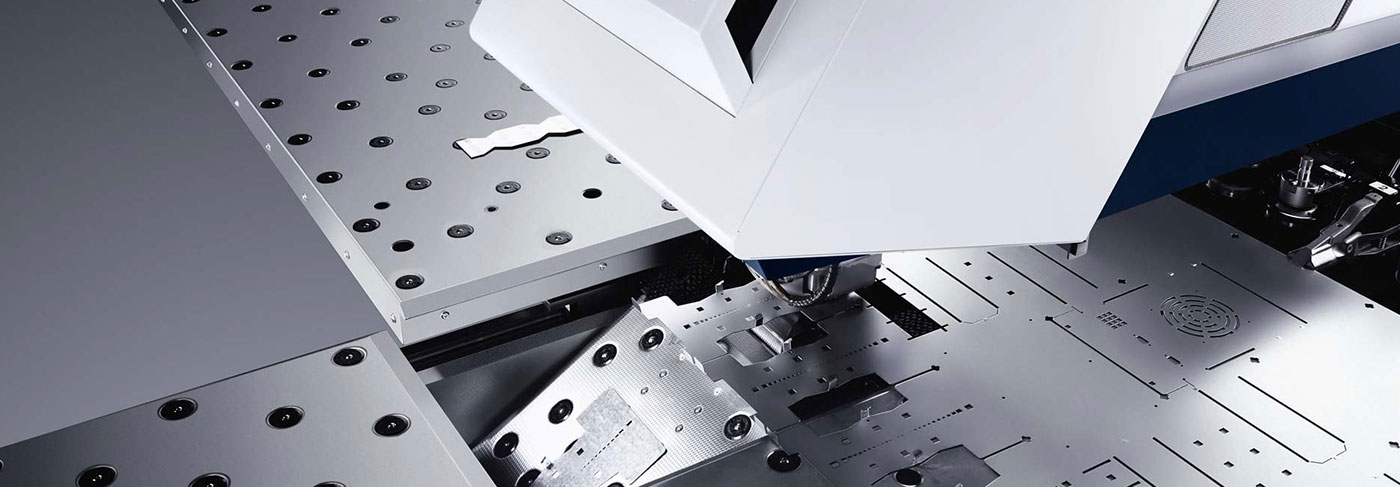

As-machined |

The standard finish for our parts, the “as machined” finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburs parts cleanly. |

All materials |

n/a |

Stain |

Learn More>>

|

|

|

Sand Blasting |

Sand blasting is the process of powerfully propelling, generally with high pressure, a stream of blast media against a surface to remove unwanted coating layers and surface impurities. |

Aluminum, Steel, Stainless Steel, Brass, Copper |

n/a |

Matte |

Learn More>>

|

|

|

Anodizing |

Keeping our parts in the long term, our anodizing process resists corrosion and wear. It’s also an ideal surface treatment for painting and priming, and it looks great too. |

Aluminum |

Clear, black, grey, red, blue, gold |

Smooth, matte finish |

Learn More>>

|

|

|

Electroplating |

Electroplated coating preserves the surface of parts and resists rusts and other defects from causing decay by applying electric currents to reduce metal cations. |

Aluminum, steel, stainless steel |

Gold, silver, nickel, copper, brass |

Smooth, glossy finish |

Learn More>>

|

|

|

Polishing |

Ranging from Ra 0.8~Ra0.1, polishing processes use an abrasive material to rub the part’s surface to make the shine more less shiny, depending on your requirements. |

All materials |

n/a |

Smooth, glossy finish |

Learn More>>

|

|

|

Powder Coating |

Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm. |

All metal materials |

Custom |

Glossy |

Learn More>>

|

|

|

Wire drawing |

Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. |

ABS, Aluminum, Brass, Stainless Steel, Steel |

n/a |

Satin |

Learn More>>

|

|

|

Painting |

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic. |

Aluminum, Stainless Steel, Steel |

Custom |

Gloss, semi-gloss, flat, metallic, textured |

Learn More>>

|

|

|

Passivation |

Stainless Steel |

None |

Unchanged |

5μm – 25μm |

Learn More>>

|

|

|

screen printing |

Aluminum, Brass, Stainless Steel, Steel |

Varies |

N/A |

< 1 µm |

Learn More>>

|

|

|

Black Oxide |

Black oxide is a conversion coating similar to Alodine that is used for steel and stainless steel. It is used mainly for appearance and for mild corrosion resistance. |

Steel, Stainless Steel |

Black |

Smooth, matte |

Learn More>>

|

|

|

Alodine |

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts. |

Aluminum |

Clear, Gold |

Same as before |

Learn More>>

|

|

|

Part Marking |

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production. |

All materials |

Custom |

n/a |

Learn More>>

|

|

|

Knurling |

Knurling is a unique finishing process designed to indent a component to make it easier to grip. |

All materials |

Same as before |

Matte |

Learn More>>

|

|

|

Heat Treatment |

Heat treatment enhances mechanical properties, relieves stresses, and refines the microstructure of metals, enabling them to meet specific performance requirements for a wide range of applications. |

Steel, Stainless Steel |

Dark grey |

Same as before |

Learn More>>

|

|

|

Pickling |

Pickling describes an acid bath designed to remove oxide scaling from a component’s surface. |

Steel, Stainless Steel |

Dark grey |

Same as before |

Learn More>>

|